| Panel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||

Projecttitel: Arp1601 CloneStatus:

Startdate: end of 2014Duedate: Summer 2015last update:August 201608/2020 rev.6B infosthe Name and logo "ARP" is under license by Korg, this pages are for private usage only. Its not allowed to sell your 1601 Sequencer with the brand or logo of "Arp1601" |

pay attention to your PCB Version.

the latest Version is rev.6b (available from Synthcube), which is different from rev.5

(DC-DC adaptor on rev.6A is the same as in rev.1-5)

(DC-DC Adaptor on rev.6B is a Meanwell 6Watt Version)

you find the BOMs on the left side navigation/subpages

rev.3 update: (Summer 2016 jhulk's pcb run)

C42 = 1nF c0g Capacitor

C5 = 33nF or use 39nF Filmcap or ceramic cap

Muffwiggler Thread:

https://www.muffwiggler.com/forum/viewtopic.php?t=110640

Muffwiggler Build Thread

https://www.muffwiggler.com/forum/viewtopic.php?t=138862

| Attachments | ||

|---|---|---|

|

| Gallery | ||||||||

|---|---|---|---|---|---|---|---|---|

|

Buildeguide for rev.5 which is mostly the same like rev.6b (except the PSU, SMT resistor network)

old rev.1-4 in left navigation or here:

Buildguide rev.1-4, there are a lot of documents in this older buildguide version

PCB Designator/Component Numbers

ARP 1601 Sequencer Rev 4 - PCB (full).pdf

the most important change to earlier versions:

Changed:

2x LM3046M SMT instead of CA3086 THT (rare part)

1x MC14528 SMT instead of rare THT Version

All Slider Switches changed to other versions.

Panel holes for 3.5mm jacks bigger

lets start:

we start with the SMT Parts:

use 0.3mm or 0.5mm soldercore with lead and a small soldertip, add a small solderpoint at one solderpad on pcb.

doublecheck the IC orientation - check my picture for details.

touch with the solder iron the pad where you added before the soldercore, now is your IC fixed, check the correct allignment between the IC pins to the pads.

solder at the outer pins at beginning followed by the other side, dont give the too much heat, good tutorials are at youtube for SMT soldering or ask me to assist you.

second step, Powersupply

what you need to know:

you can power the Sequencer without the internal PSU, if you have a Arp2600 or TTSH, you can use the -15V/15V for the sequencer too, thats why you find a power input (3pin MTA100 close to the DC-DC part) (PL1 on PCB)

internal power:

place and solder (with a big soldertip) the DC-DC adapter on the PCB, solder one middle pin and check the correct placement, sometimes its not close enough on the pcb.

add the L3 (12uH inductor), L1&L2 are ferrite beads., place and solder the 47uF, 2x10uF capacitor and 2x 100nF ceramic disc cap, feel free to add the 3 pin MTA100 header for external input(output)

add the 2 big MTA156 2 pin header on pcb (on left side) thats for the powerswitch and one for the 12V DC-36V DC Power input (PL1)

for testing you can bridge the PL4 header (switchheader),

solder all powersupply parts and cut the "part legs/pins " short.

now you can test the powersupply for correct output, it must be measured at the MTA100 power input header (PL1) -15V/15V

only if this voltage is correct, build further steps (around +/- 14.8-15.2V)

Step 3:

Add few spacer on the pcb to have a distance between the desk and pcb

start with the 0.1% resistors..

followed by fat 650R/680R/750R resistors (LED DRIVER Resistors)

then: 1K,10K,100K, 22K

followed by all other values, solder from top side one pin, turn the pcb and solder from solderside (thats what i prefer)

Step 4:

add all capacitors and Transistors and solder ..

Step 5: IC sockets and more

add all IC sockets on same pcb side like the resistors, ignore the silkscreen notice about sockets (that means the 6.3mm jacks)

place and solder the 2pin MTA100 (PL2 ) thats the external footswitch input,

remove all spacer and mount the 11mm spacer on the solderside of the pcb.

Step 6: Sliders

Place the Slider on opposite side of the resistors (you see it on my pictures),

bend few pins to give the slider a temporarily position.

about the 3x 45mm sliders: the FM slider (R14) in the middle is 100K log. (ignore the google doc BOM)

Step 7: jacks

add 2 jacks at the outer positions in place and solder one pin, that helps us later to fix the frontpanel here, because there's no spacer on this side.

only 2 jacks yet.. more on step 9 later

Step 8: Switches

add all switches and the 3 cherry pushbutton switches, solder only the middlepin on the switches temporarily !

Step 9: more jacks

add all other jacks in the position, DONT solder it yet.

Step 10: Frontpanel & more

mount the frontpanel, use the 2 jacks to give the panel on the right side a temporarily fix.

now you must carefully check the alignment, hight, positions of all sliders, jacks, switches.

my best practice tip: solder not so much yet, only 1-2 pins per switch than check again the alignment by using of the switch.

Step 11: IC´s

turn the sequencer on a clean flat desk/table and insert all ICs, double check the orientation.

Step 12: first test

before that: use a jumper at the 2pin MTA100 (PL2 ) thats the external foot switch input, or the sequencer wont start.

move the Switch to trigger, move the clock speed slider to 10-30%, the FM and PW slider to zero.

turn on the sequencer, the STEP LEDS must be move from step to step . clock LED blinks (if not move the slider) and the FM/PWM slider must be illuminated all the time.

IF NOT, power off the machine, remove power, check IC orientation

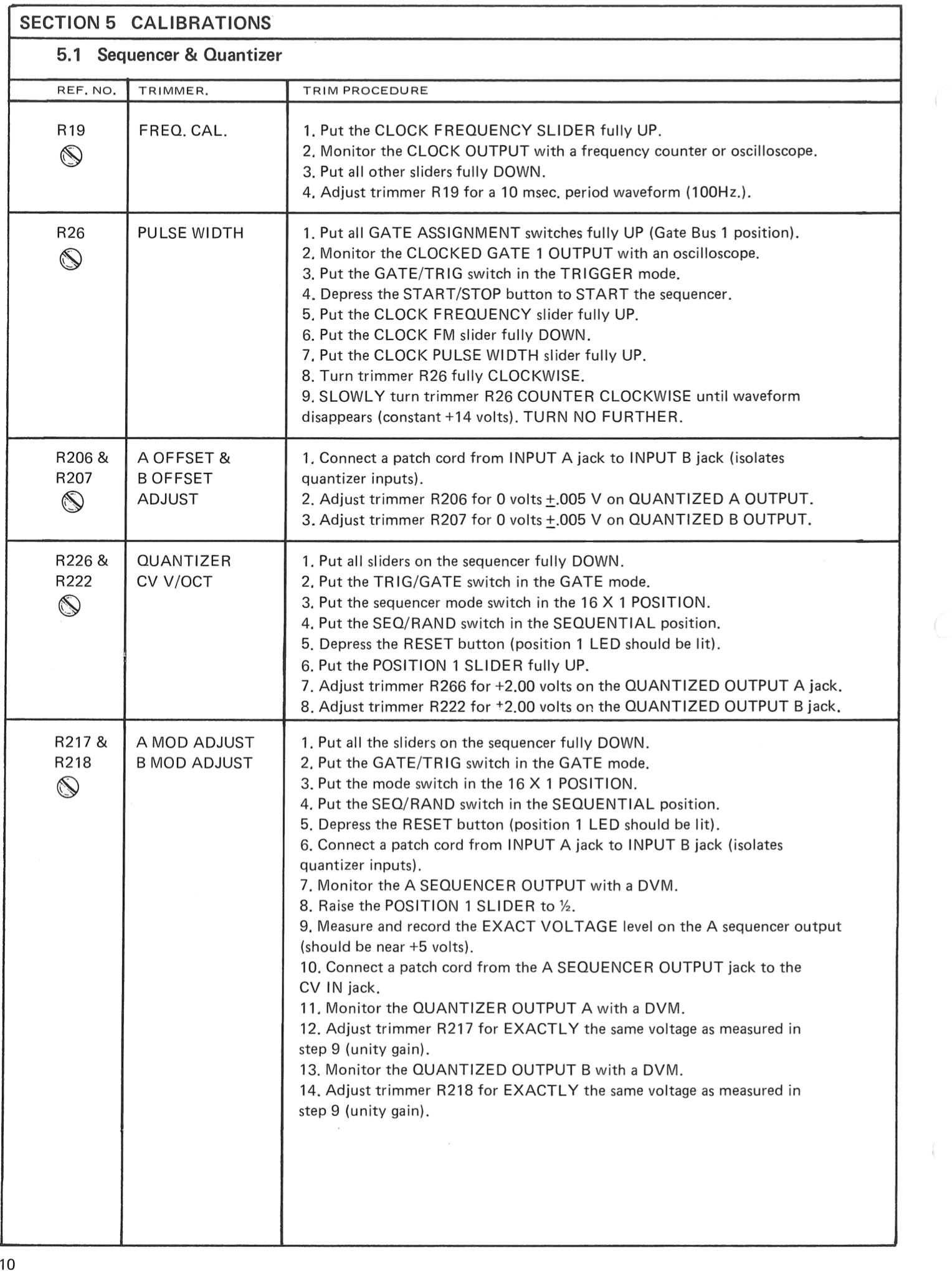

Step 13: Calibration

use the original ARP1601 service manual for it.

Step 14: finishing it up

about the Footswitch, if you dont need the footswitch: use a PC jumper for the PL2 (same as Step12) or connect a switched stereo 6.3mm jack, the TIP is the signal, ground must be normalized to switch pin - when you dont have a 6.3mm plug inside, the tip must be flow to ground.

mount the frontpanel in the boat, the boat is not in the correct allignment - because the metalboat was bend by machine and the metal bounce more or less after this process in different way, that was happen on all metalboats over the last years.

→>> not

OLD rev.2 buildguide only for reference - thats not the actual guide, but it helps you in case of failure

|

NOT APPROVED for REV.5 version !

Schematics from rev.1, not compared to rev.5 ! but its 99.9% the same inside.

BOM: (BOM update 12 jun.2015)

please see attachment list above

the file: ARP1601_PartList_ sorted is sorted for resistor and capacitor values -please use this for building ARP 1601 Parts List_sorted.xls

for Kipplings groupbuy round2 you need a 12uH Inductor and 47uF/25V cap too (this parts are not in the BOM)

Mouser part nr.: 652-RLB9012-120KL and 1-off 667-EEU-EB1E470SH

for Round 1 BOM: dont buy the expensive ferrit bead on mouser.. this part dont fit.

please use: 2x 875-28L0138-80R-10

keycapps: 3 needed - if you buy the keycap kit, it includes 14caps (instead of 13)

Builders Guide: (left rev.1 - right rev.2)

|

|

Known Issues: (rev1. and rev2)

The start/stop pushbutton is a little prone to contact bounce giving multiple triggers. The ever-helpful Nordcore has a fix involving changing one IC, two additional resistors and one capacitor and one track to cut with a little point to point wiring. Unfortunately it is too late to incorporate these changes into the round 2 PCBs so they will remain as PCB rev 2. A quick fix kippling have tried with good success is increasing C5 to 33nF, and adding a 1nF capacitor soldered directly across the SW1 terminals, and for me at least gives no noticeable lag.Further tips will be added as I think of them or they are pointed out by users

Mods for Start/Stop: As mentioned above change C5 (10nF) to something around 33/39nF, and add a 1nF directly across the pins of SW1 to eliminate the contact bounce causing the unreliable start/stop push-button operation.

take a look at Page 9 of the Buiders Guide rev.2 (for Rev.1 Users are this fix too)

further its possible to change the IC "Z1" CD 4011 to CD4093 for the start/stop issue, cut on frontpanel pcb side a trace add few R/Cs (1M and 10nF ?) - see this pics:

Mod: Clock Frequency (thanks to Ultravox)

source: https://www.muffwiggler.com/forum/viewtopic.php?t=138862&postdays=0&postorder=desc&start=25

I was able to get the Clock Freq slider to work full travel by increasing the resistance of R17 to approx 222.5k. I didn't have a resistor of that value so I put a 100k trimmer in series with R17 and adjusted it so that the clock will still operate when the slider is set to min. The Clock Freq slider now gives 1Hz - 100Hz from min to max travel.

Schematics (round 1)

ARP 1601 Sequencer - Schematic (round 1).pdf

Panel:

|

| Gallery | ||||

|---|---|---|---|---|

|