Projecttitel: RE-808

Status: DONE

Startdate: 11/2021

Duedate: 12/2022

Last Update: 14.Sep.2023

Manufacture link: https://shop.re-303.com/product/re-808-bundle-3rd-run-advance-order/

source: own build.

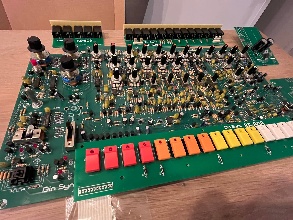

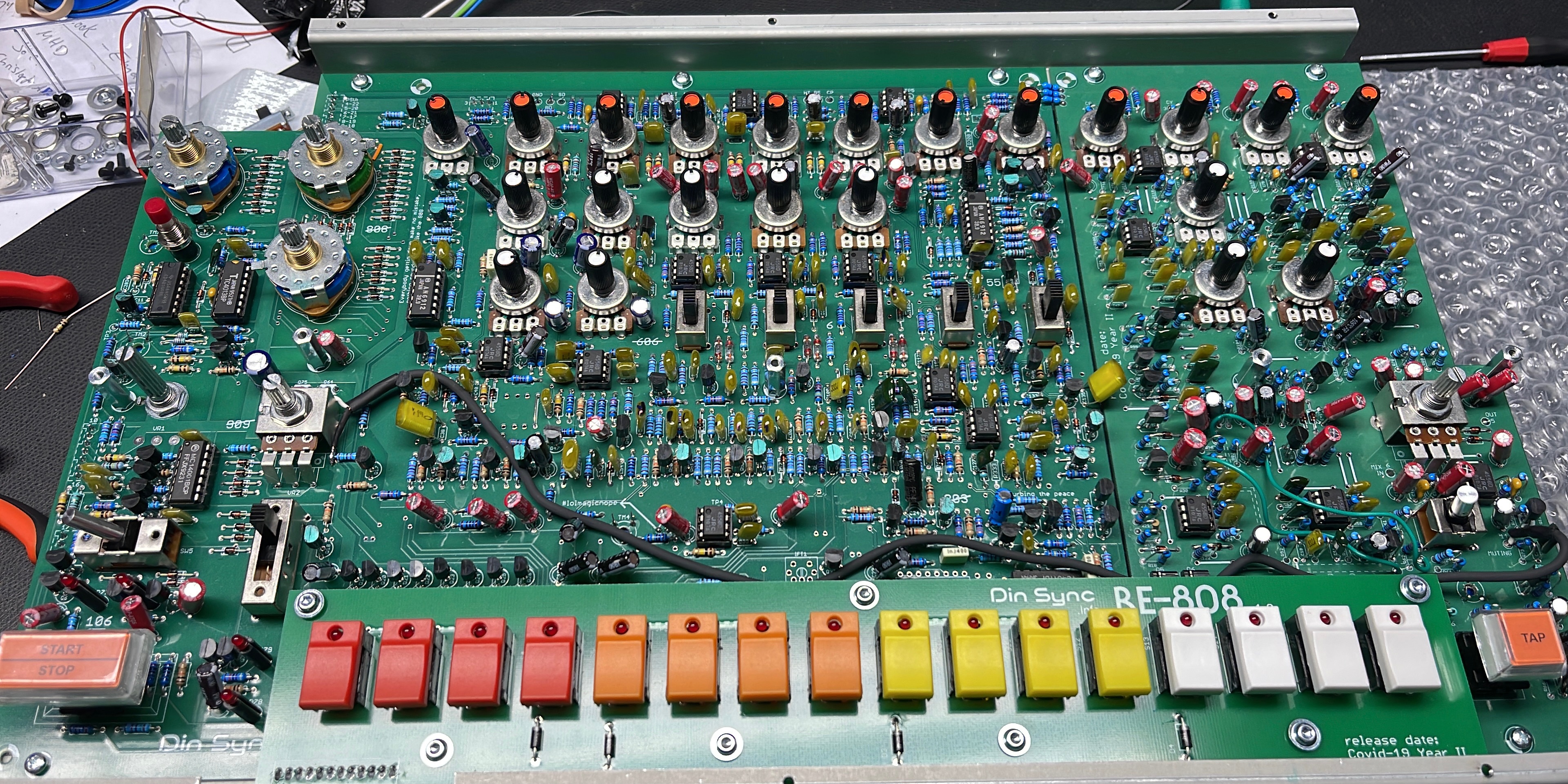

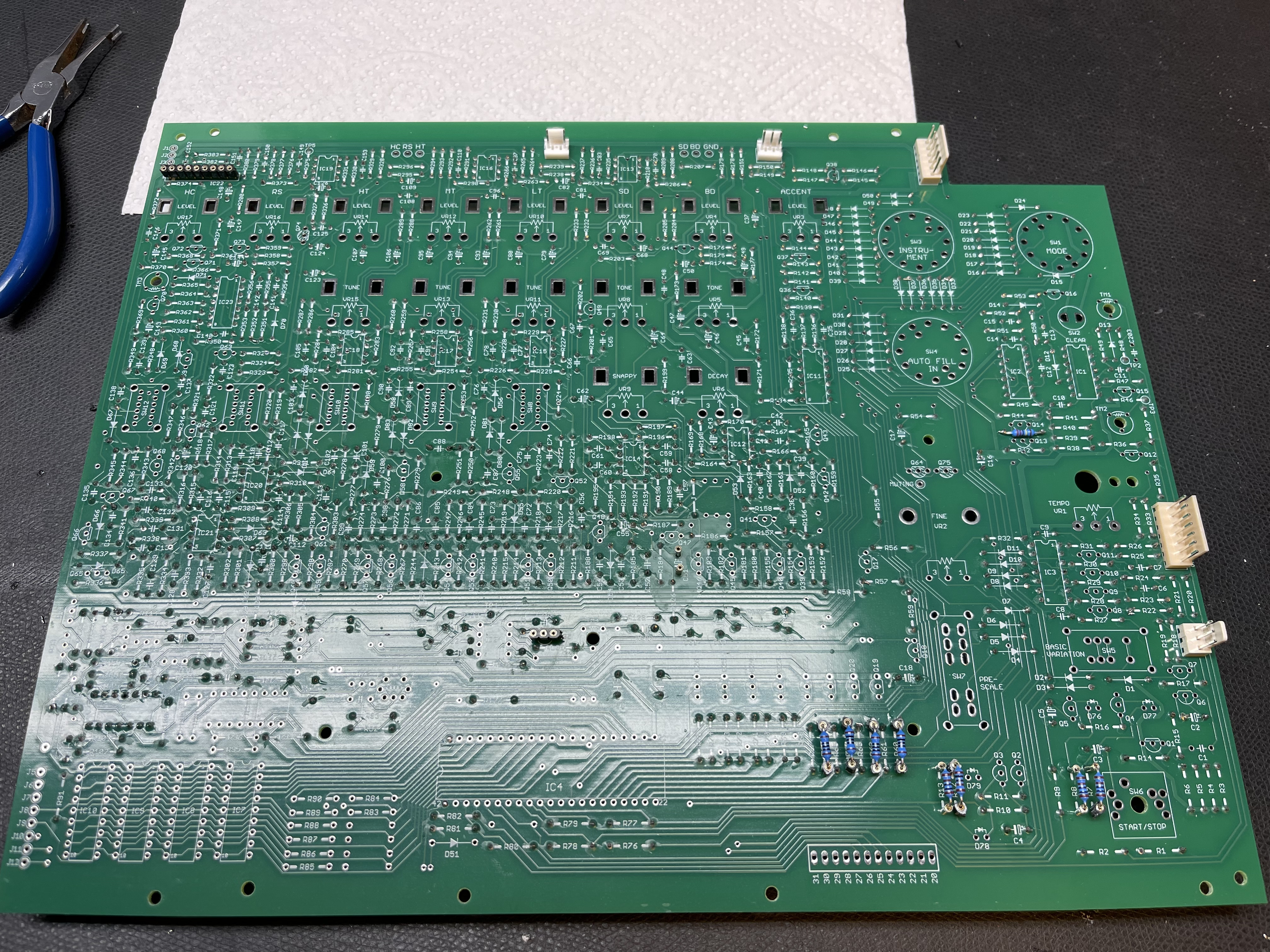

after the RE-303, RE-606, RE-909 we have the RE-808 replica to build.

its an replica, which means 99.9% of everything is a replica - the pcbs, the case, the parts.

the only difference are replacement tactile switch of the sequencer.

but you can repair your TR-808 with the RE-808 parts.

Infos and groups:

https://www.facebook.com/groups/1095915370823319

BOM:

PCBs and some parts are available from the RE-303 shop

Cases and side panels are available from Kumptronics

Start/Stop cover and Tap cover for the switches can be made byself with 3D rosin print, or ask me.

please read this: https://shop.re-303.com/files/files/Making_your_Start-Stop_and_Tap_buttons.pdf

Standoffs/Spacers (not in the BOM - but supplied with the RE-808 case)

7x 8mm FF Hex Spacer for the mainboard thru switchboard

4x 10mm FF Hex Spacer for the PSU

5x 16.4mm FF Hex Spacer for the mainboard

3x 18mm Hex Spacer for the bottom case part

2x 8mm MF Hex Spacer 8mm w/ 6mm Screw for the EMV shield plate

Buildguide: (uploaded 08.May.2022 by DSL-man)

RE-808 Switchboard Assembling v1.0.pdf

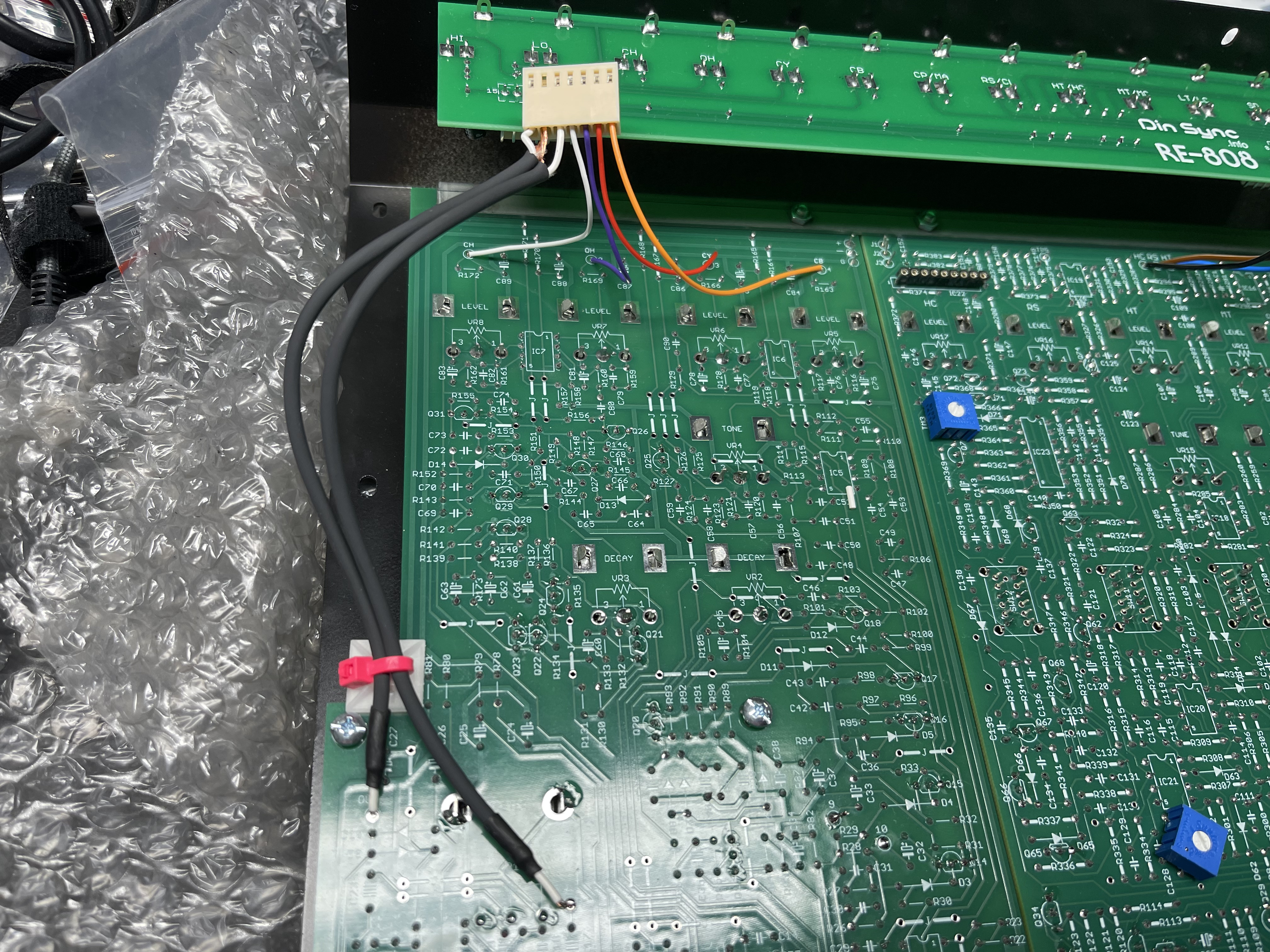

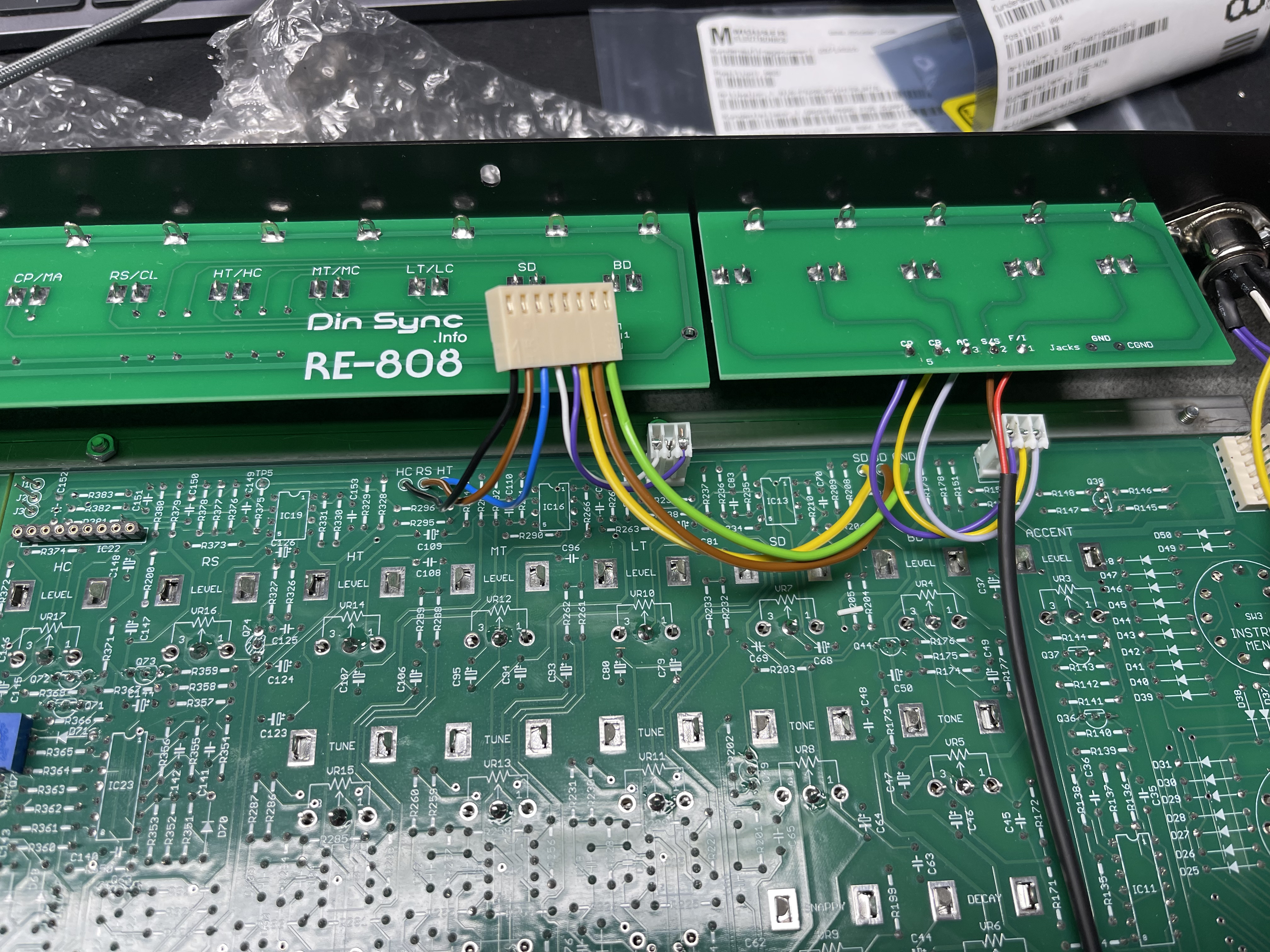

Alps Switches Modding Guide v1.0.pdf

RE-808-MYC-manual-midicable.pdf

RE-808 Case assembling guide. RE-808 assembly guide.pdf

Placement guide:

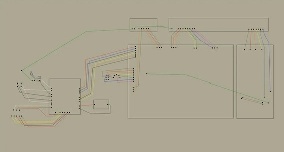

RE-808_Component_Placement_Guide_v1.0.0.pdf

Firmware Installation

warning: before you do this make a break and double check all parts, especially IC orientation & Pixie orientation, the wiring - especially power and sync switch and sync jacks.

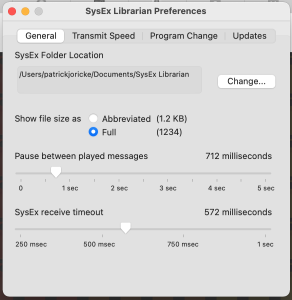

use Sysex Liberian to upload the files

settings in SysEx tool:

- turn on and send 808.sysxex with sysex librian tool (step1 led is blinking) (when not - check your MIDI wiring)

- now send the the boot loader 1.4.3 with sysex librian tool (step led is blinking)

- turn off the machine

- in boot loader mode (hold step1 while start) upload the REEMU 1.4.3 sysex (normally step1-9 show the progress while uploading), when it doesn't show the nightrider mode by pushing step1 while starting the machine: check your wiring of the sync switch,

https://github.com/sunflowr/recpu/releases/download/v1.4.3/recpu_manual.1.4.3.pdf

Issue List

| ID | Issue | Fix | date | fixed version |

|---|---|---|---|---|

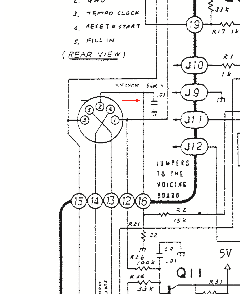

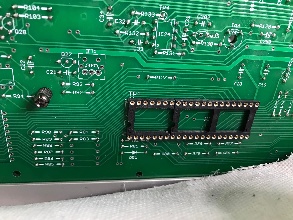

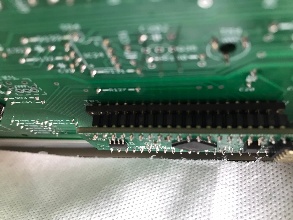

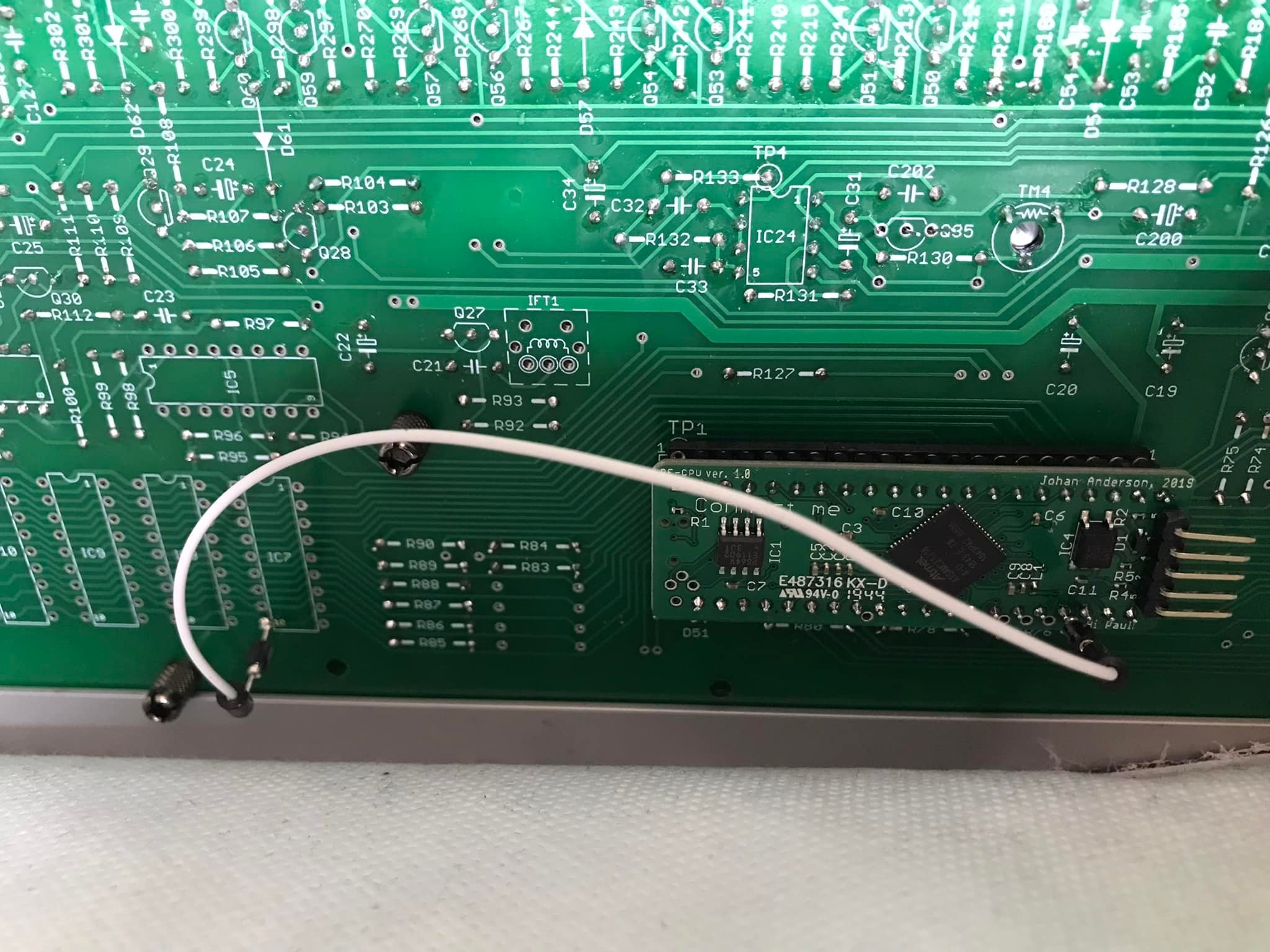

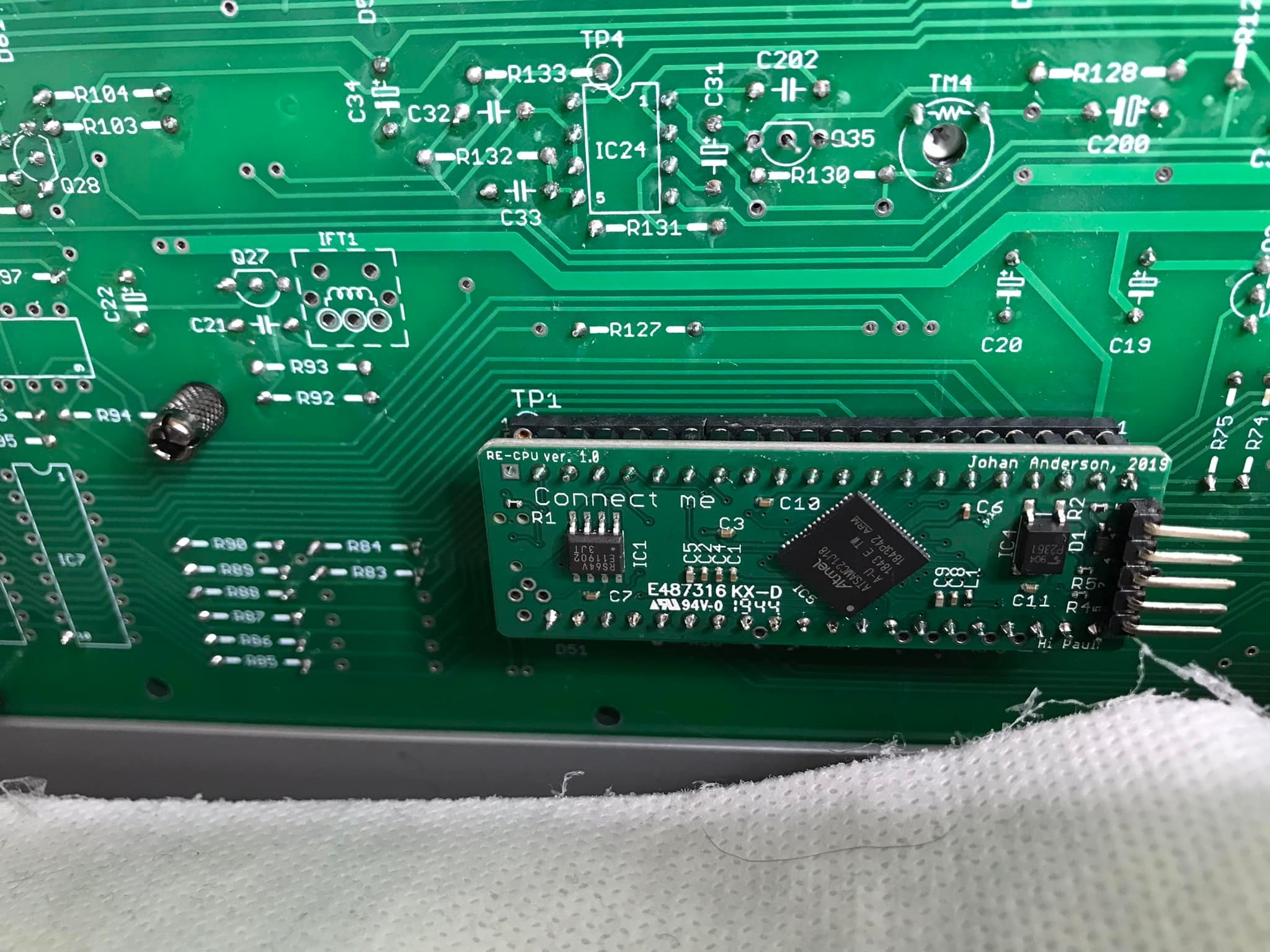

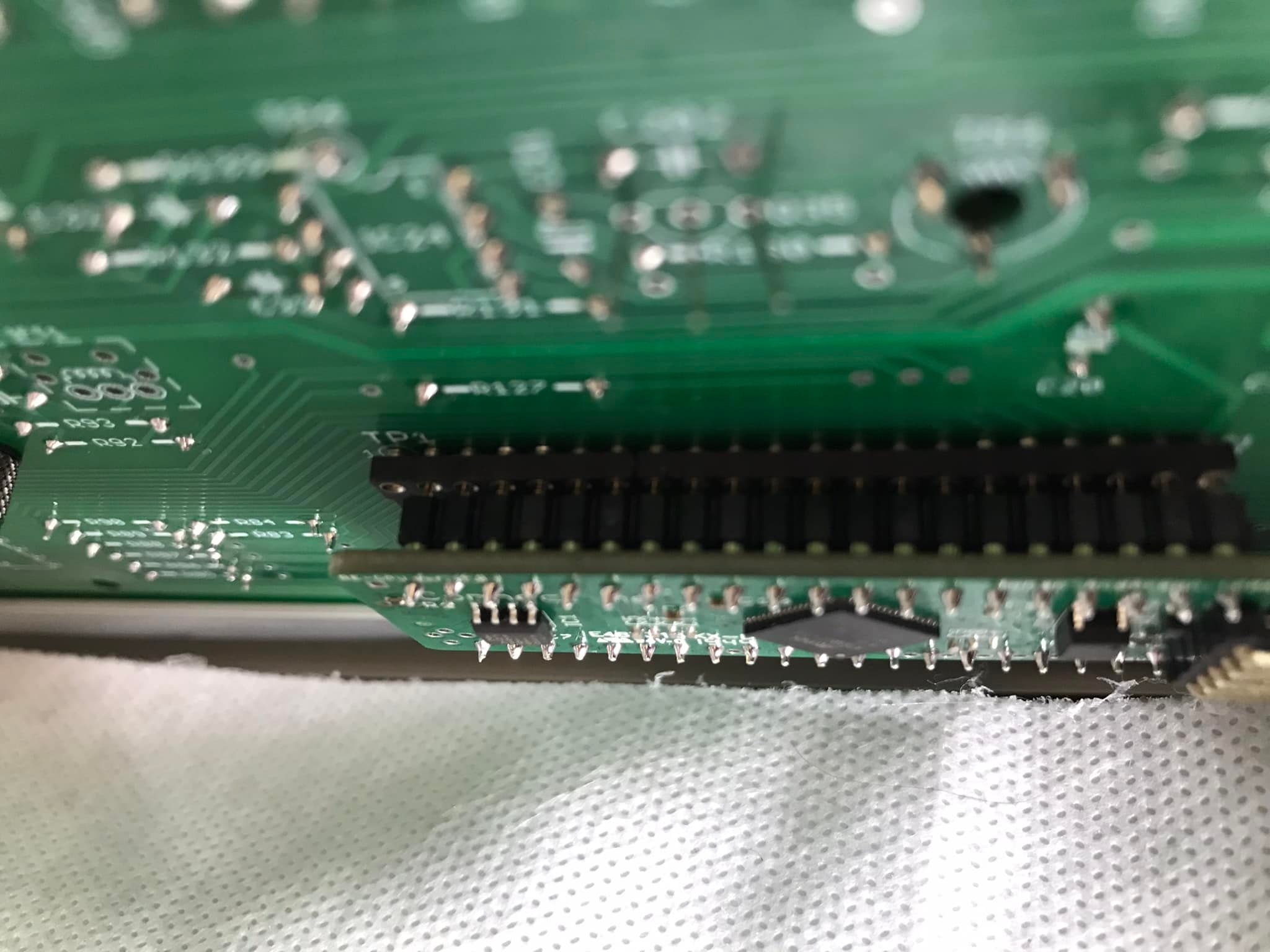

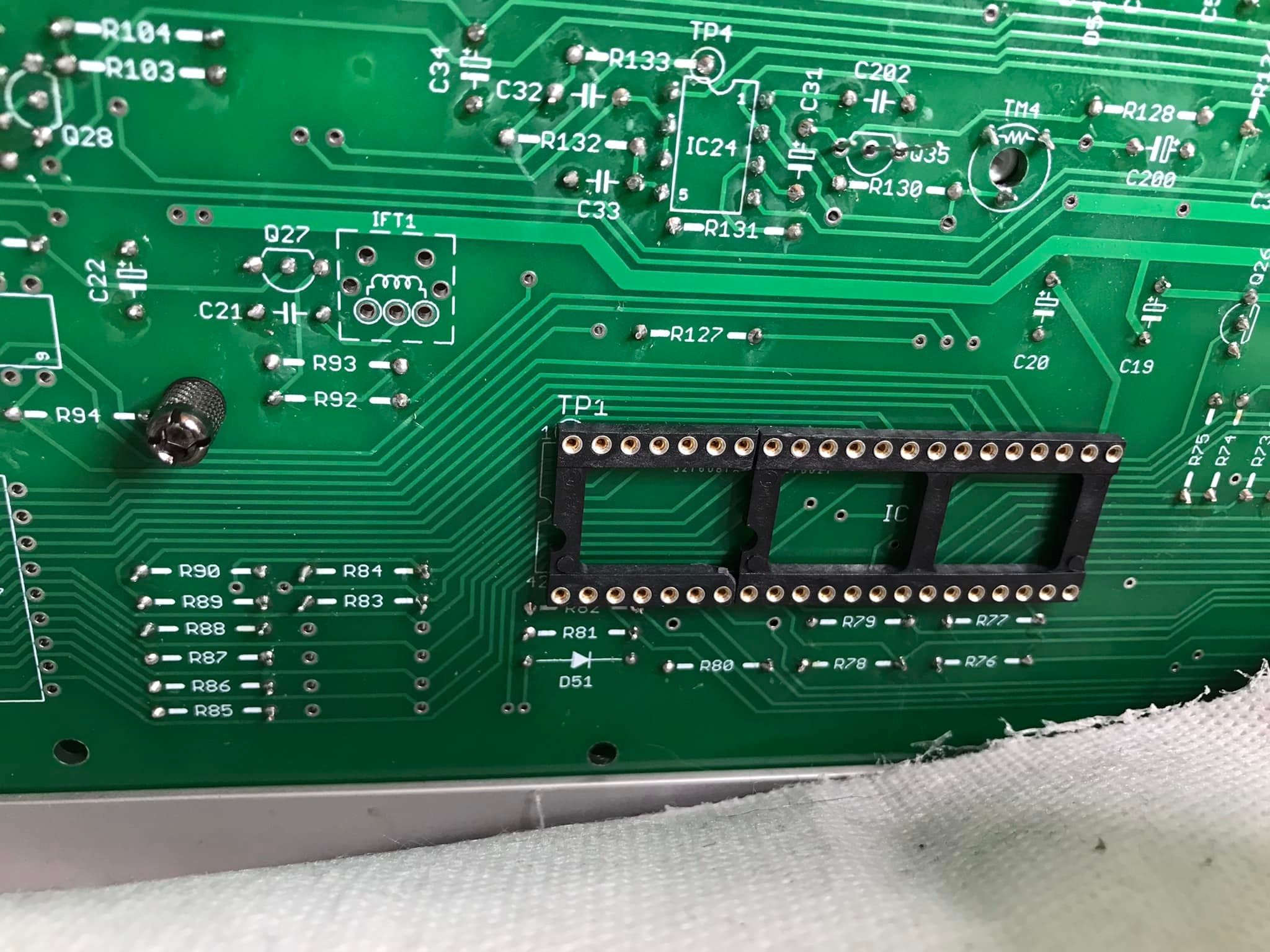

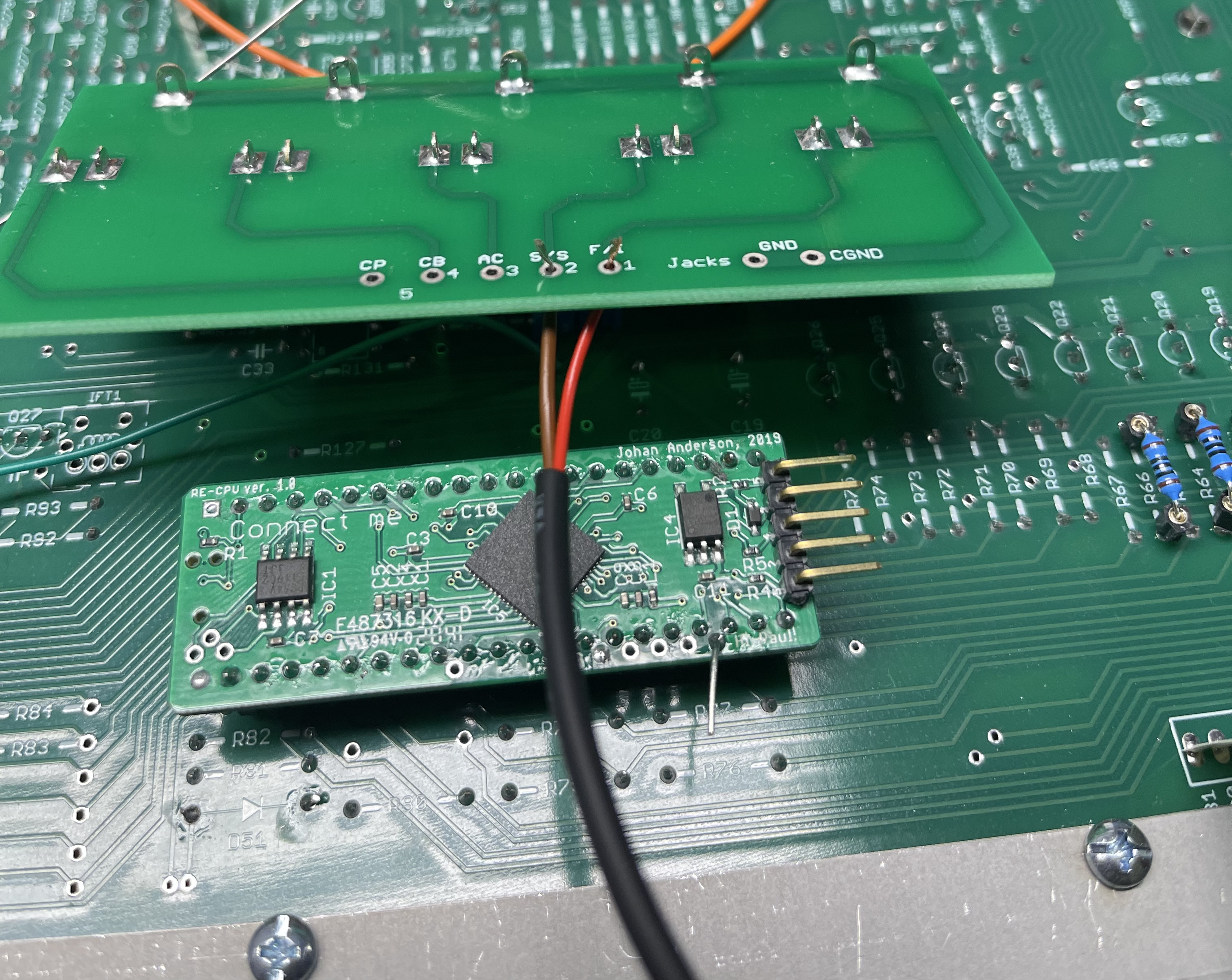

| 1 | CPU mounting | As you can see you also need to do a jumper wire between the solder point marked A on the pixie cpu and pin 10 (!WE pin) of *any* of IC 7,8,9 or 10 (they’re all connected to the same signal) | 01/2022 | |

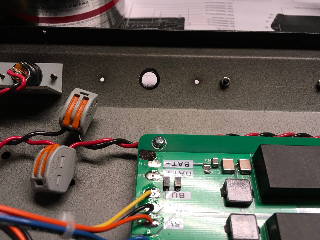

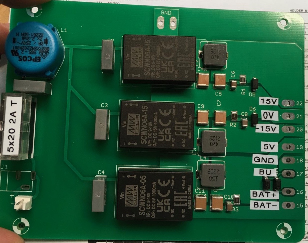

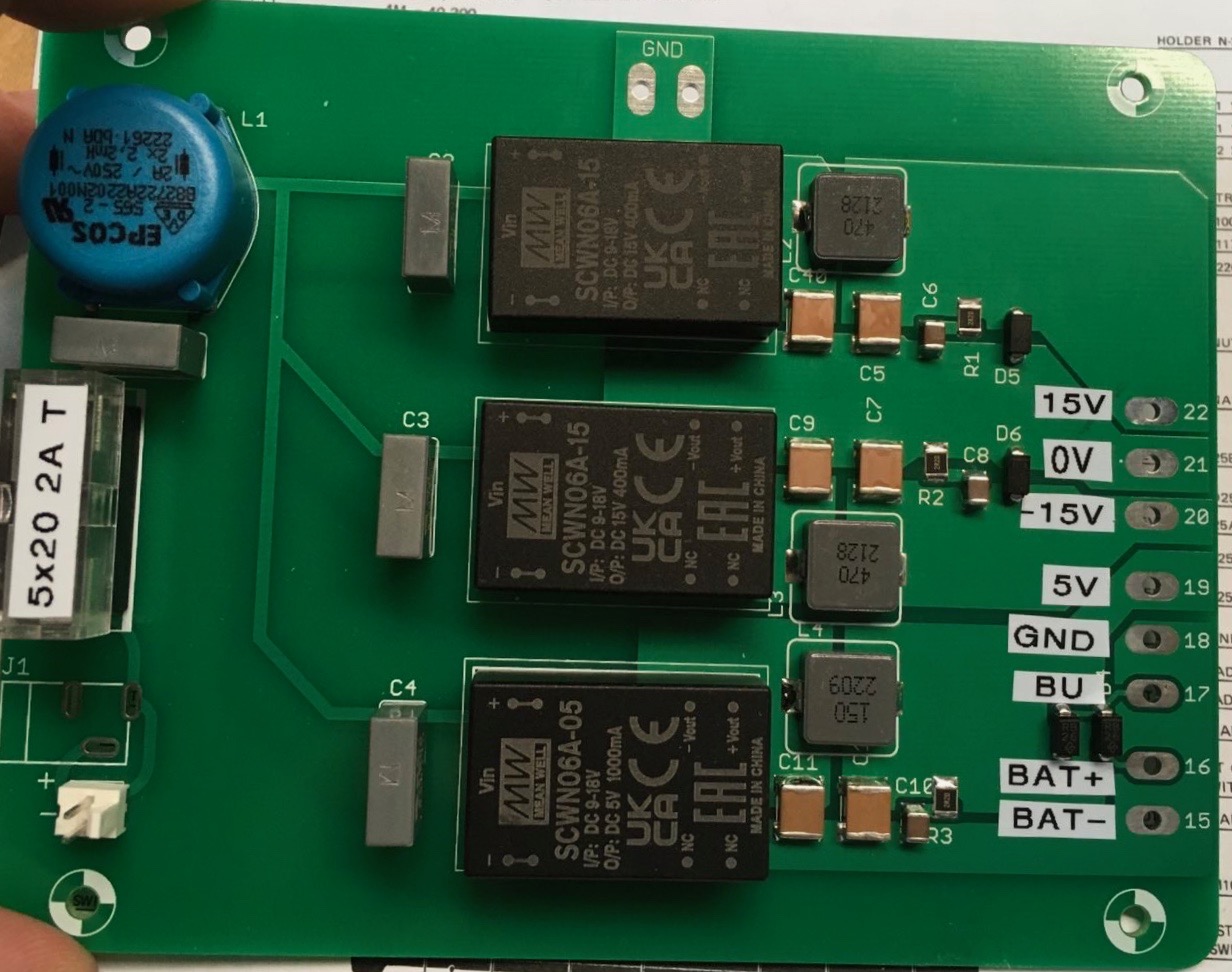

| 2 | PSU | Do not fit the DC jack on the PSU circuit board. Its not used and it is not wired correctly. use a cable for the jack as shown for example | 01/2022 | |

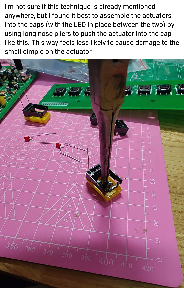

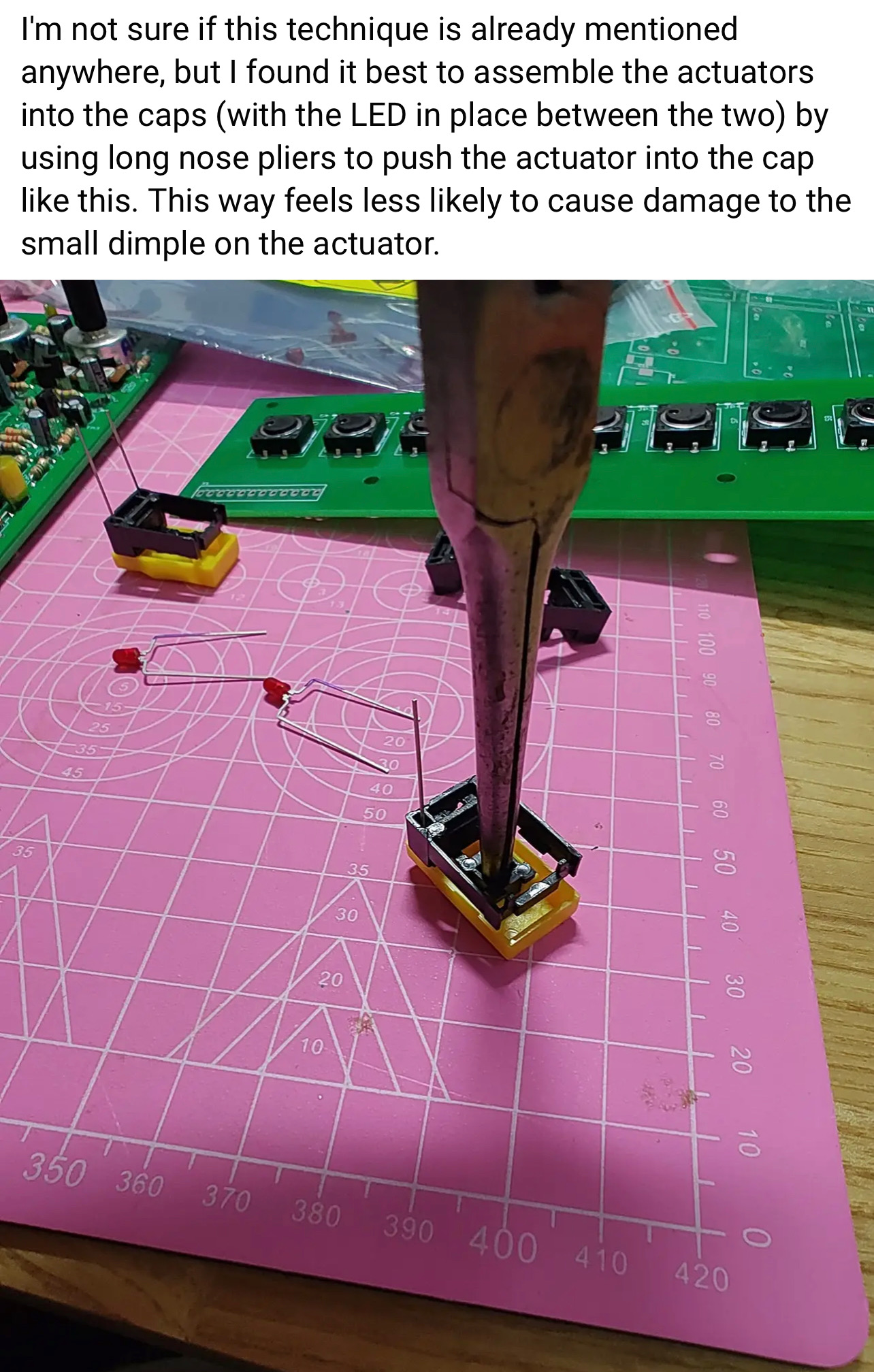

| 3 | Tactiles /caps install | heres a tip about the installation of the tactile caps: i prefer this process: | 01/2022 | |

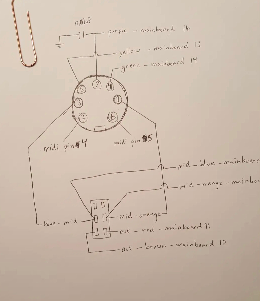

| 4 | MIDI WIRING | credits to a FB User.. | 11/2022 | |

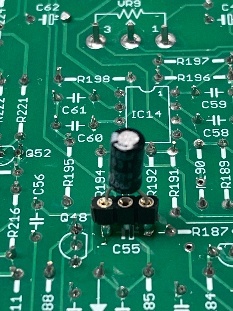

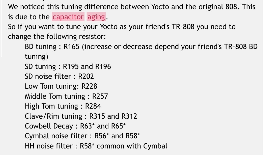

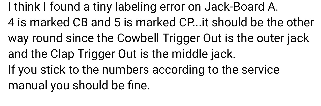

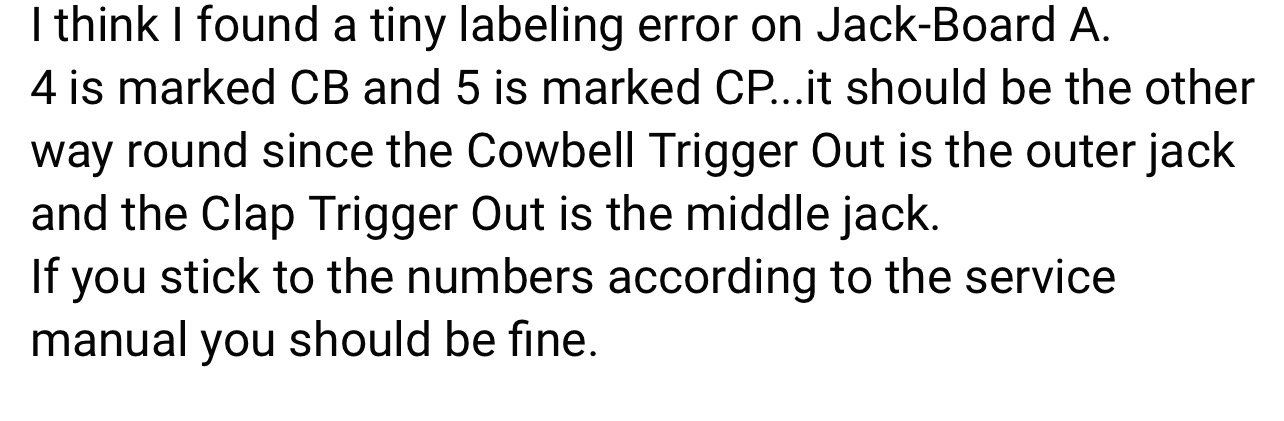

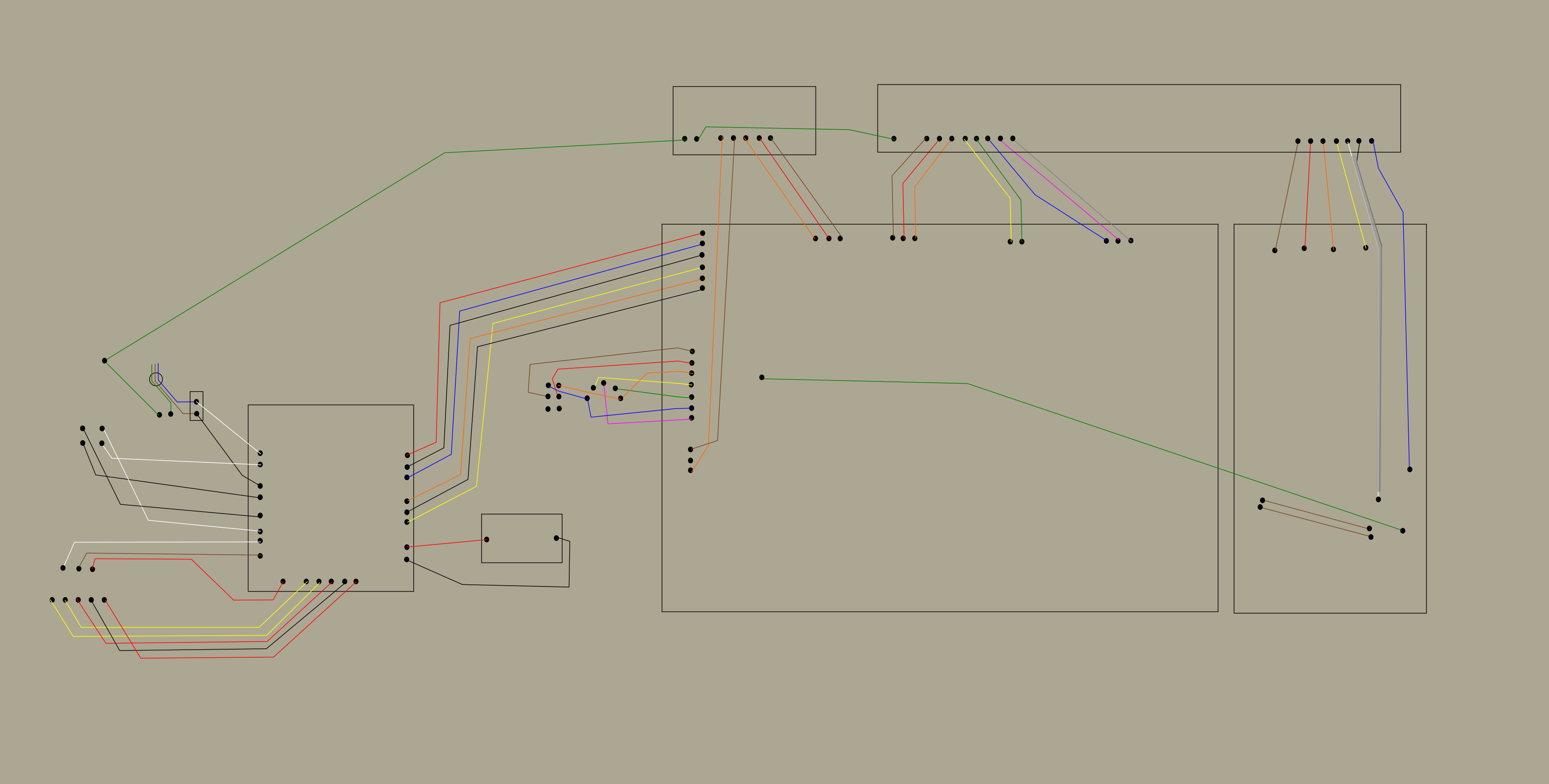

| 5 | Silkscreen wrong | 11/2022 | ||

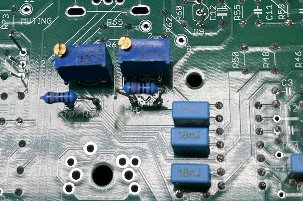

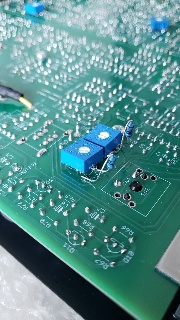

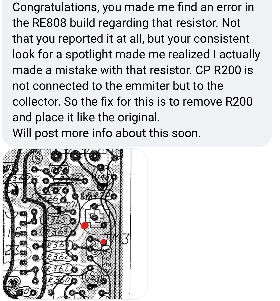

| 6 | Mainboard resistors - handclap | in case you have the trimmer on solder side (recommended) Add the R200 (10K) as shown in the left picture above at the 2 red dots. | 11/2022 | |

| 7 | guide /tip | for the voice board: first install all 1/8watt resistors on bottom of the pcb R1-9 are 1/8w or the switchboard do not fit use MLCC caps there and no IC socket. for IC1. when you have a solder frame: install the flat Trannys and ic sockets before you install the other parts for mainboard use for the noise transistor and muting trannys - ic socket pins to swap/change the trannys install good trimmers from nearside instead cheap trimmers from component side - better calibration possible | 11/2022 | |

| 8 | Transistors - sequencer failure | use sockets for the muting transistors. some users reported issues in combination with the pixie CPU, boot/start problems. the muting Transistors affect this - you can remove this. | 1.Dec.2022 | |

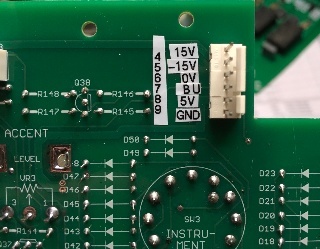

| 9 | Power Pinout |

credits by Martin.J.K - Thank you | 02.Jan.2023 | |

| 10 | general | install good trimmers on back side (solder side) - for easier calibration install the BA662 clone on solder side - in this was you can use a socket install the muting JFETS and noise Transitor on solder side for easier swapping install R333 on solder side to give you the opportunity to replace this with a trimmer (50k) to change the handclap sound.. | 02.Jan.2023 | |

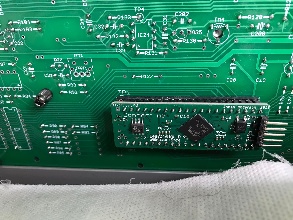

| 11 | bugfix | install a jumper as shown to get your 808 working as designed | 03. Jan.2023 | |

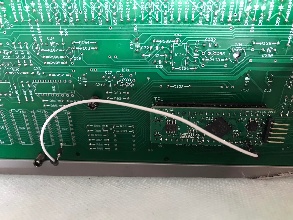

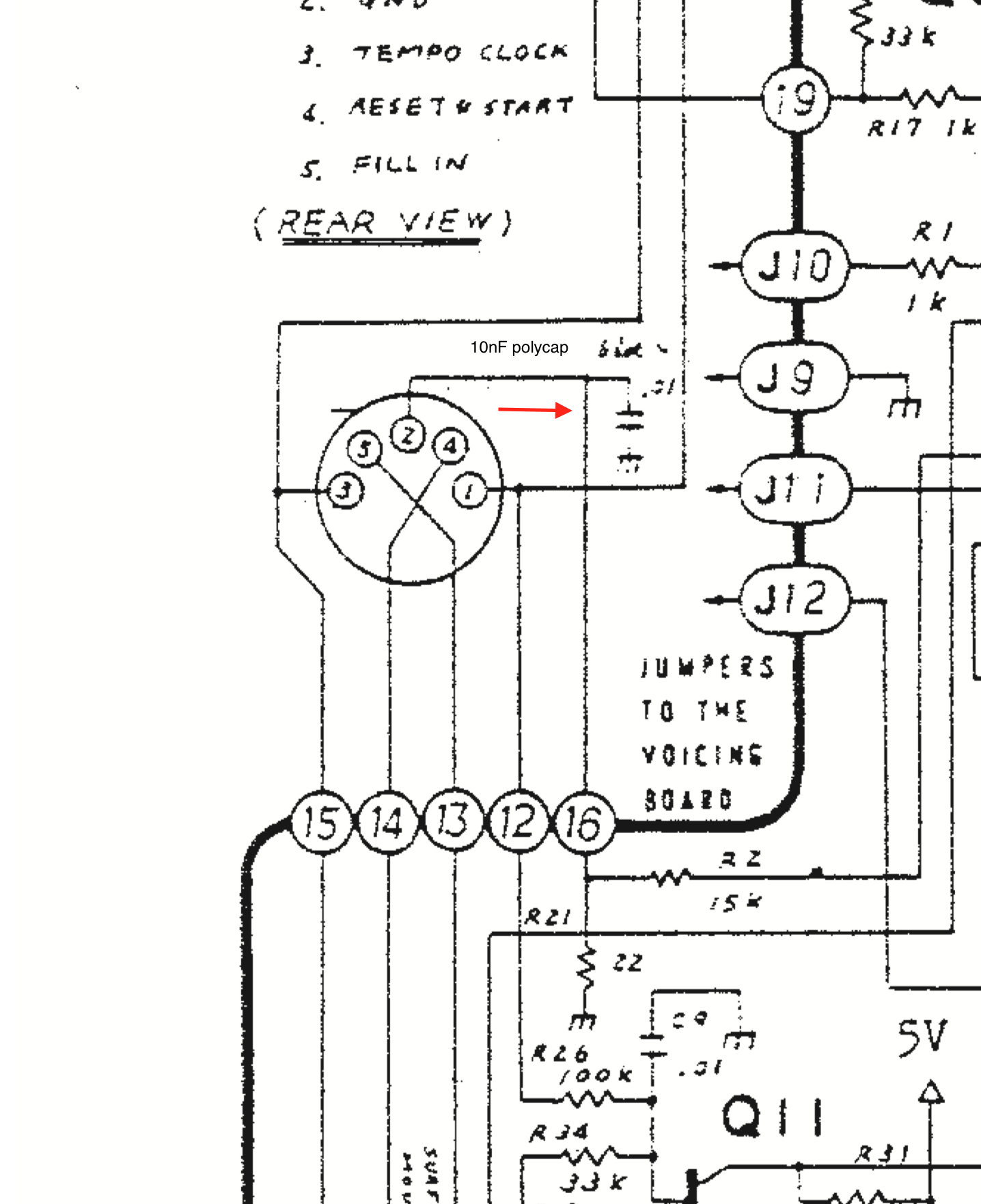

| 12 | capacitor on Sync jack | install a 10nF polyester cap or bipolar electrolyte cap at the sync jack or on the pcb | ||

| 13 | clock calibration fix | remove C203 on mainboard (39nF) or your clock can't be calibrated in case you can't reach 120hz by trimmer end, install a 2M2 resistor in parallel on R43 | 04.Jan.2023 | |

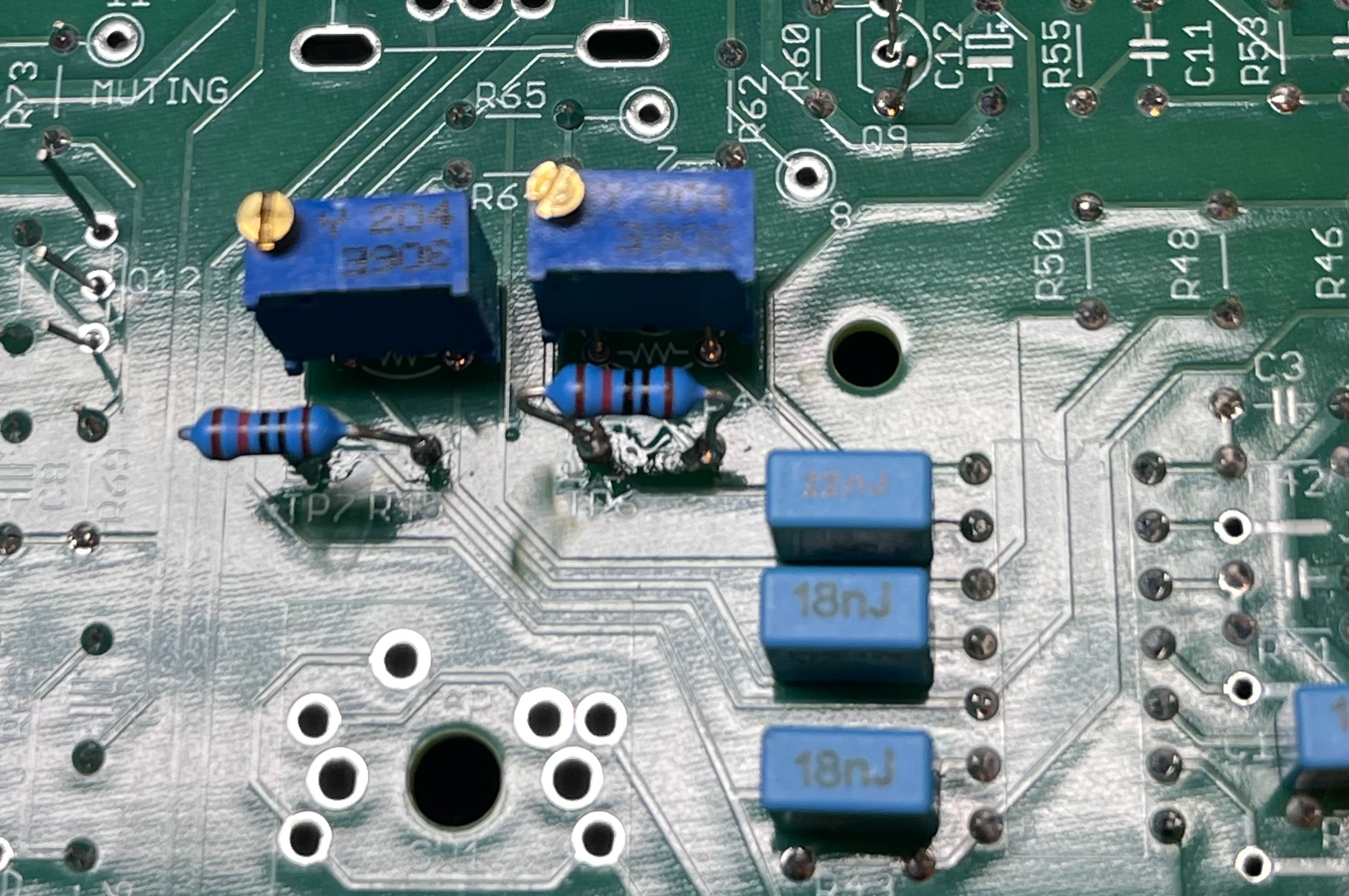

| 14 | calibration/mod | Hi tom noise level = R273 BassDrum Endless/Extended Decay -- replaced R170 (470k) with 370k resistor in series with a 100k potentiometer. then i set the potentiometer to the 'sweet spot', where the extra decay sounded best to me, and measured the resistance of the 370k resistor plus the resistance of the potentiometer setting. on my Yocto, 445k was the nicest value for self-oscillating/extreme decay . then i removed the 370k resistor and potentiometer from R170, and finally replaced R170 with an SPDT switch that selects between a 470k resistor (the original value/normal setting) and 445k (the 'sweet spot' for extra decay i measured, using a few resistors to achieve the 445k value). source: https://www.e-licktronic.com/forum/viewtopic.php?f=18&t=143 | 02.April 2023 | |

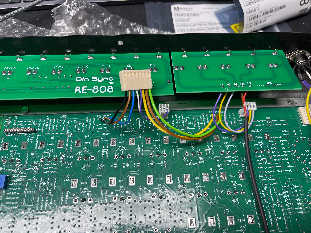

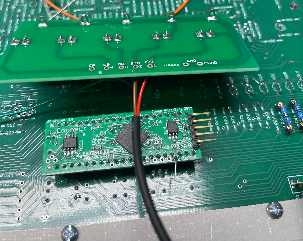

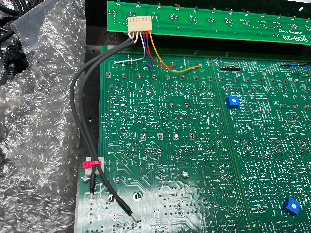

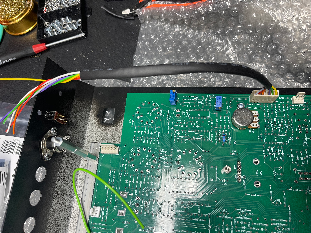

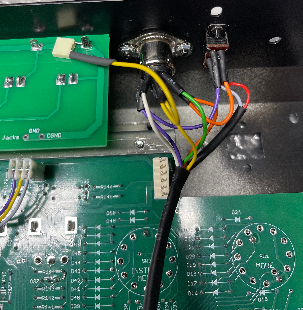

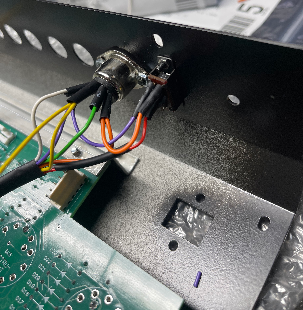

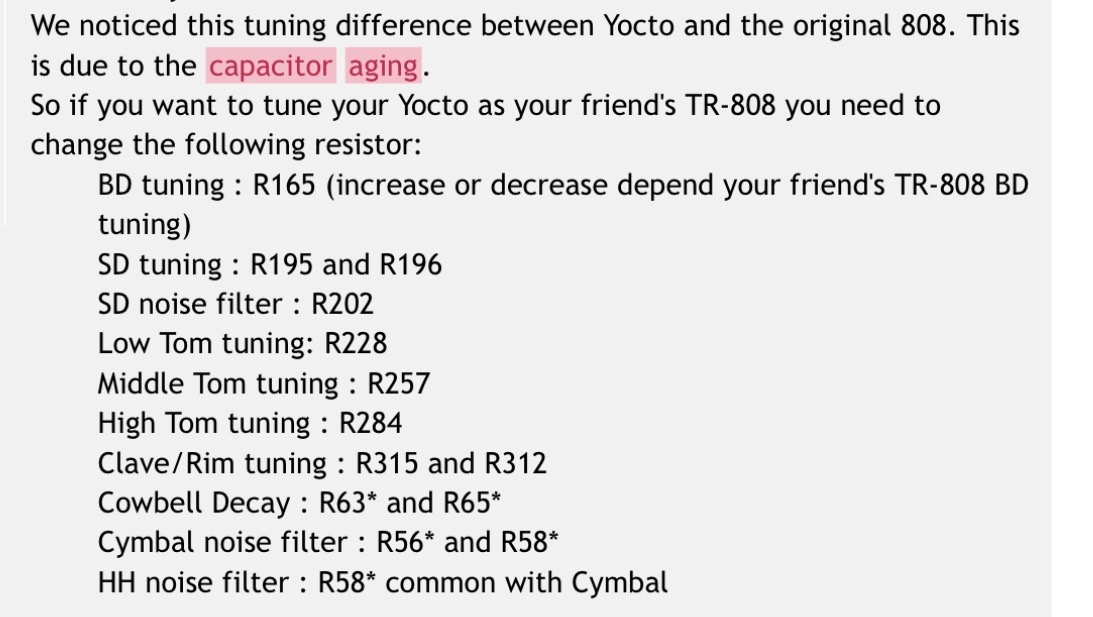

| 15 | wiring | found on FB - bad quality of the picture... you find on bottom pictures of my builds which can be more helpful - especially for the sync switch wiring new 07/2023 - HD quality : 808-wiring.png | ||

| 16 | wiring | |||

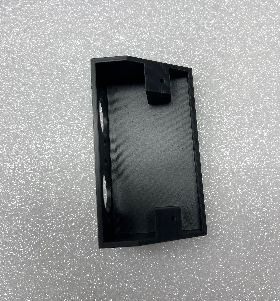

| 17 | MIDI connection MOD | the 3D printed part is available in my shop https://www.diysynth.de/spezial-re-808-parts/re-808-midi-anschluss-3d-druck.html or print it myself (Resin preferred) just use 2 screws to mount this at the typenumber plate holes at the rear and drill a small for the MIDI cables.

| ||

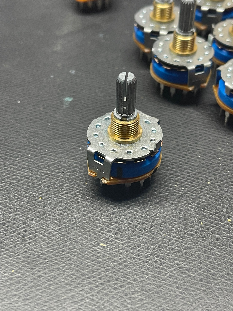

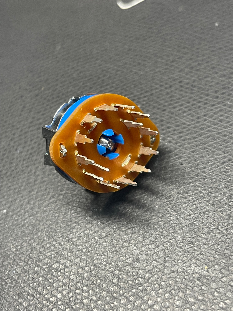

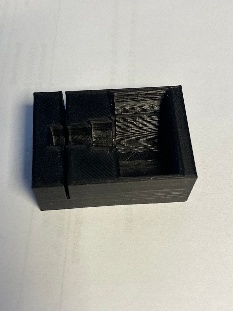

| 18 | 3D Print tool rotary switch | this tool make things easier. just drop the rotary switch inside and its easy to saw the switch, but you should need file the length 1-2mm shorter (depends on your knobs and if you want the knob as close as possible against the case) available in my shop : https://www.diysynth.de/spezial-re-808-parts/re808-schaltersaegehilfe-3druck-teil.html | ||

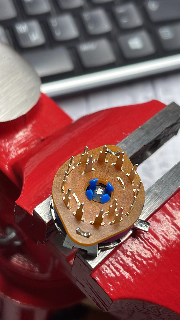

| 19 | Tip Rotary Switches | for much easier rotary switch assembling, use this knowledge PLUS the ALPS assembly guide, my infos are a additional tip how to remove and bend the tabs. you need in total 3 rotary switches 2x 6Positions, 1x12positions endless all 3 switches must have a knurled shaft and the length must be since we can't buy this from stock we have two buy in total 6 rotary switches and make from this 3 rotary switches. you can follow the alps rotary switch guide which is attached at top of this page but you should read my improved tips how to remove/bend the switch.. Background: we dont need the upper part of the D shaft switches (we need knurled shaft for the 808 knobs) and we don't need the lower part of the mouser/digikey knurled switches. that's how you prepare the switches: for the D shaft switches you can bend the tabs at the bottom for removal as close you can - because we dont need the upper part - put the upper part (metal) in the trash bin, we only need the base(bottom part incl. blue plastic)

for the assembled knurled switches you can cut the pcb on bottom to remove the bottom part without bending the tabs, after you have removed the pcb - you can much easier bend the tabs !!! we only need the top metal part of this switch.

after you proceed the other steps as described in the alps rotary switch guide , you have to bend back the pins which hold the bottom part and upper part. I used here 2 tools and a hammer. in first step I punched with the smaller hex. and the hammer and later with the bigger hex. and a hammer. In case your switches wobbles, you can add 2K glue from the sides of the switches (metal to pcb) but doublecheck that no glue comes in contact with the blue/green plastic part. furthermore, you have to use a nut and washer to mount the switches on the case | ||

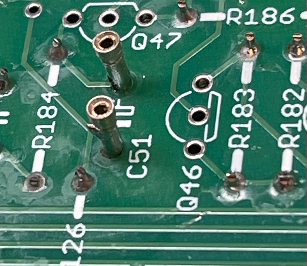

| 20 | recommend Mods for Clap and Snare | remove R333 and install a 50K trimmer from solder side - this adds the opportunity of changing the Clap frequency/bandpass Install a header for the Noise Tranny of the PCB Solderside - you can try different Noise transistors of your choice (less white noise at the snare, gain stage between handclap and Snare, a loud Handclap is wrong, too much white noise at the snare is wrong) forget the 133mV AC measurement of the noise Tranny - the important thing is the spectrum of the noise. use a transistor tester (peak tech for example to get the correct polarity or use the datatsheets) Furthermore: (highly recommend) you change c51 from 0.47uF to 0.68uF (or up to 1uF) to get more reverb/room on the Snare. use milled pins on the solderside for testing the value. Only do this mod when you are lucky with the snare sound except the reverb part is too small (personal choice) its not recommend to do this mod until you have found a good noise transistor otherwise you have too many variables. | 02.April 2023 | |

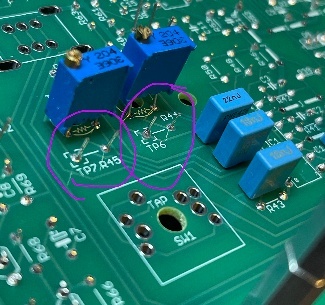

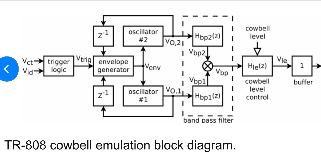

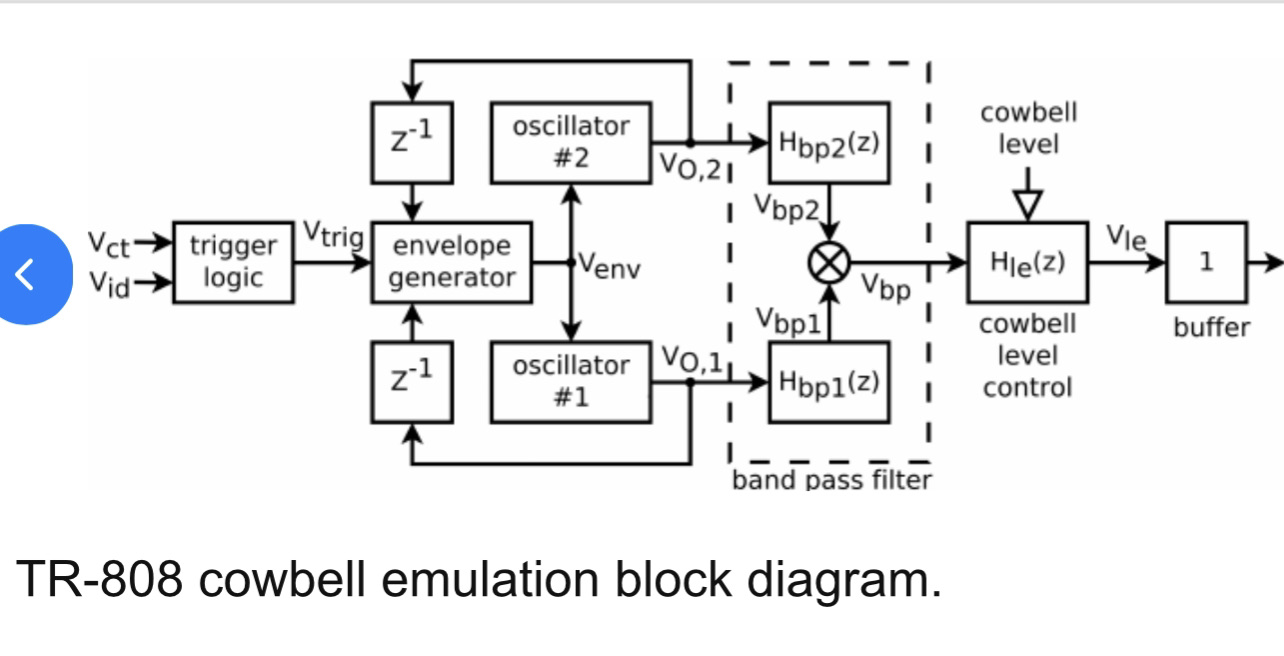

| 21 | Cowbell bugfixing | in case your cowbell is out of the trimmer range while calibration 800hz/540hz install in parallel to R44 a 10K resistor and the same for R55 (add a 10K in parallel) since we connect a scope there, let enough space to clip the probe there.

in case you have failures in the cowbell, here's a good page: visit http://frisnit.com/roland-tr-808-cowbell-rebuild/ | 02.April 2023 | |

| 22 | Grounding /wiring | Connect the "Chassis GND" from the safety PSU directly into the Jacks A "Chassis GND". Do not wire it thru the chassis. Connect Jacks A to Jacks B. | 02.April 2023 | |

| 23 | Cymbal Mod | source: https://www.modwiggler.com/forum/viewtopic.php?t=264016 change :The modification involves changing C40 (in the middle branch next to the 33k resistor) from 1µF to 100nF Raising C41 gives a longer decay- (not tested by me) Technical paper: tr_808_cymbal_a_physically_informed_circuit_bendable_digital.pdf | 04.April 2023 | |

| 24 | general tip | mount the DIN jack from inside of the Case - don´t install the DIN socket thru the metal case, in case of trouble shooting its much easier with the wiring - otherwise you have to disconnect/desolder some cables. | 06.April 2023 | |

| 25 | general | Here are few pictures, how I installed LED resistors on sockets, to change easily the brightness of the LEDs. recommended: 680R instead of 68R for the step led brightness R60 R62 R64 R66 and 1k or more for the 4 other LEDs. R7 R8 R12 R13 I used in one of my builds flathat LEDs for the variable/pattern LEDs with 1K resistor and there's no issue that other leds are still on/glow. | ||

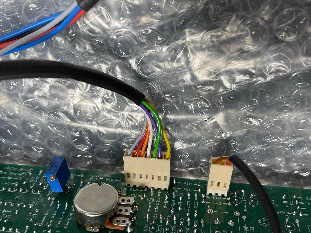

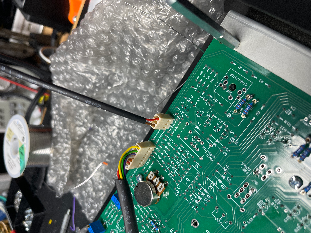

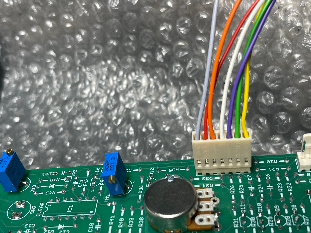

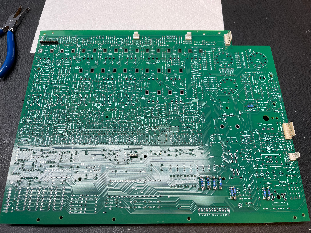

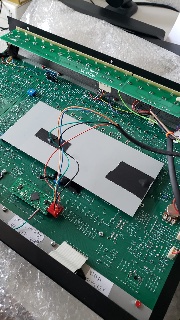

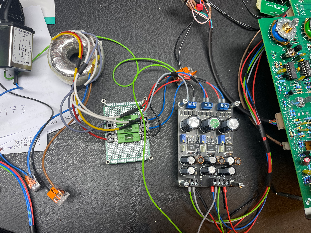

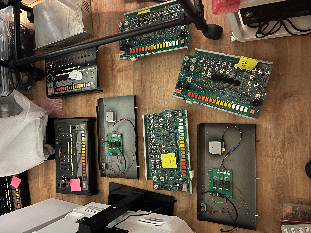

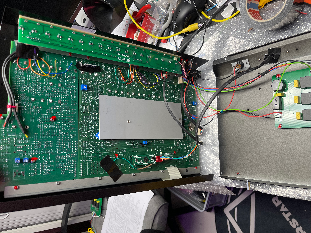

| 26 | wiring | few users requested some pictures of the wiring.. |

Gallery own |

|||

|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

3 Comments

tje030

the images showing the wire connections of din sync and switch, does "mid" in the wiring guide means orange and blue (din 1 and 3) should be attached to the middle connectors of the switch?

LED-man

It’s important to understand the circuit.

Please look at the schematics.

There’s a picture where you can find the switch. Maybe I find tomorrow time to draw a illustration.

tje030

I think i got it. If 12+11 and 15+10 are connected via switch sync is going out. Interrupting the cirquit via switch sync is going in. So the order where to solder does not play a role as long as this is given.